Quality Control

Quality control is essential for customer satisfaction and business success.

Professional Management System

We Only Use the Finest Materials

The finest raw material for silicon carbide (SiC) heating elements is high-purity, high-density, and highly crystalline silicon carbide powder. The purity of the silicon carbide powder is crucial, as impurities can lead to defects and reduce the overall performance of the heating element. High-density silicon carbide powder is essential for creating a compact and robust structure, while highly crystalline powder ensures excellent electrical conductivity and high-temperature stability.

- High-Quality Green Hexagonal Silicon Carbide Powder

- Highest Hardness with High-Purity SiC Powder

- High-Quality Adhesives for Connecting Cold and Hot Zones

Inspection of Raw Materials

Moisture Detection

Density Measurement

Bending Strength

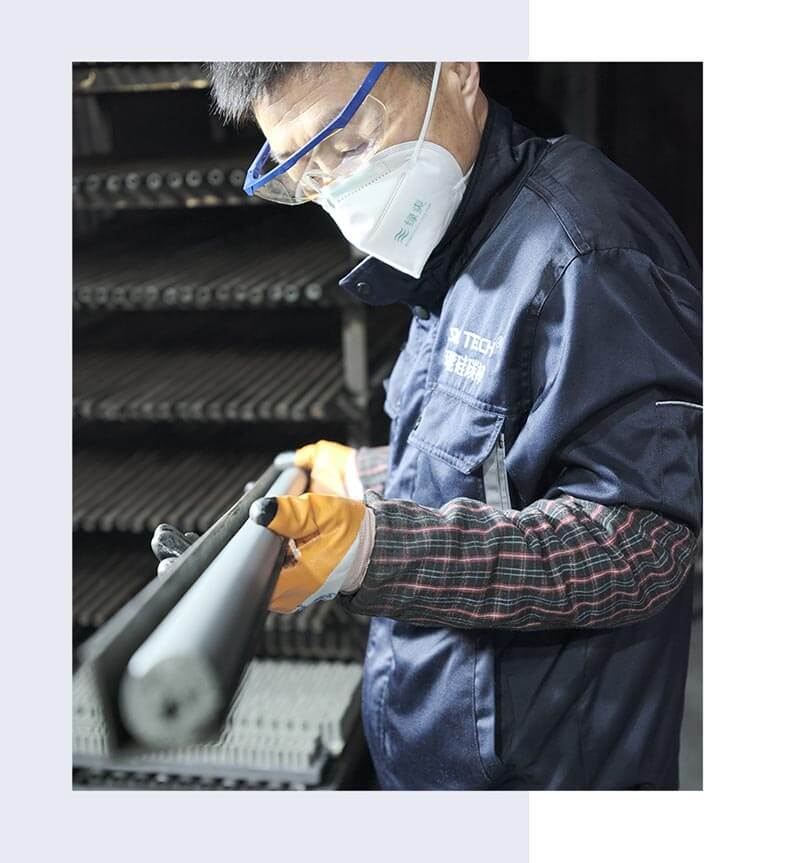

Quality Control Throughout the Entire Process

Ensuring that products meet quality standards is vital throughout the manufacturing process. Initially, ingredients must be inspected to confirm their quality. During production, the process should be closely monitored to identify and address issues early. Regular testing is essential to ensure that all products meet standards, and any problems should be thoroughly investigated. Issues must be documented so corrective actions can be implemented. Finally, post-production checks are necessary to verify that the finished products are suitable for use. Effective quality control helps maintain product standards, reduce waste and defects, and ensure consumer safety.

- Inspection standards align with European and U.S. regulations.

- Well-trained and experienced inspectors with over 10 years of expertise

- If heating elements do not meet quality standards, they will be discarded immediately.

Every Process Counts

Mixing — Forming — Drying — Inspection — Sintering — Inspection — Cutting

Mixing — Forming — Drying — Inspection — Cutting — Silicidation — Inspection

Welding — Inspection — Aluminum Spray — Packing

During production, it’s essential to monitor the process closely to identify and address problems early. Regular testing should be conducted to ensure that all products meet the required standards. Any issues discovered should be thoroughly investigated, and problems should be documented so that corrective actions can be implemented. Post-production checks are also necessary to confirm that the final products are of high quality and suitable for use. Effective quality control helps maintain product standards, reduce waste and defects, and ensure consumer safety.

Each element will be tested individually.

In the silicon carbide heating element industry, conducting a thorough inspection of each element is essential. Using unqualified elements in your customers' furnaces could lead to operational issues, increased maintenance costs, and the need for replacements. A comprehensive inspection offers several benefits:

- Ensure that every product meets your quality standards and specifications.

- Prevent any defective or non-conforming products from reaching your customers.

- Minimize the risk of customer complaints, returns, recalls, or litigation due to poor-quality products.

- Enhance our reputation and credibility as a reliable supplier or manufacturer.

Testing of Double Spiral SiC Elements

Testing of Type W SiC Elements

Testing of Type GD SiC Elements